WEG Motion Fleet Management

Monitoramento inteligente da sua planta

Desenvolvido para levar mais praticidade e agilidade na operação, manutenção e gestão de plantas industriais, o WEG Motion Fleet Management é a solução ideal para monitorar e elevar a disponibilidade da frota de acionamento industrial. Baseado em tecnologia “cloud computing”, o monitoramento dos ativos pode ser acompanhado a qualquer momento e de qualquer parte do mundo.

Com o WEG Motion Fleet Management é possível conhecer o estado operacional de motores elétricos, inversores e soft-starters de baixa e média tensão, sistemas de partida com relé inteligente (SRW), redutores, motoredutores, compressores entre outros ativos, que estejam aplicados em qualquer tipo de indústria ou instalação. Por meio da coleta periódica dos dados e um processamento avançado dos mesmos, tanto na borda (edge) como na nuvem (cloud), valiosos insights são gerados. Desta maneira, é possível estabelecer planos de manutenção preditiva, observando a condição operacional da frota (condition-based maintenance). Esta abordagem reduz o número de paradas não planejadas, otimiza as ações de reparo e acelera a tomada de decisão da equipe de operação e manutenção. O resultado final é notado no aumento de disponibilidade e redução do custo operacional (TCO, Total Cost of Ownership) da frota de acionamentos.

Saiba mais sobre nossos produtos

A Importância do Monitoramento On-line dos Ativos

Uma das principais causas da perda de produtividade e lucratividade de uma indústria é a parada de produção não planejada. A maioria dos eventos de manutenção corretiva poderiam ser evitados, se os componentes das máquinas e equipamentos estivessem sendo monitorados continuamente (on-line monitoring).

A solução WEG Motion Fleet Management é uma ferramenta de alto nível para equipe de operação e manutenção monitorar e gerir a frota de acionamento, por meio de hardware para aquisição dos dados, gateways para envio à nuvem e software para visualização dos dados e análise avançada. Com WEG Motion Fleet Management é possível implementar uma metodologia de manutenção preditiva, bem orquestrada, e observando a condição operacional do ativo.

Conhecer a condição dos ativos de modo on-line contribui significativamente para otimização dos recursos de operação e manutenção como a gestão de peças sobressalentes, aumento da disponibilidade dos ativos e a redução de custos (diretos e indiretos). Adicionalmente, abordagens deste tipo contribuem com aumento da vida útil dos ativos, já que, em geral, uma falha repentina resulta em stress e degradação dos elementos mecânicos e elétricos dos equipamentos.

Main Features of WMFM Solution

- Asset tree for organizing hierarchy (customer account, units, plants, assets) and measurement points;

- Registration of equipment by type, with construction;

- characteristics to determine failure frequencies and criticality

- Bearing database for diagnostic support;

- Visualization of assets on geographic maps, in an asset tree and multi-level navigation;

- On-demand and periodic reports on equipment, assets and plant operation;

- WEGsense®: technology to detect incipient mechanical failures;

- WEGsync®: technology for multi-sensor synchronous measurement for structural vibration analysis;

- Customization of tolerances for temperature, global multipoint vibration and spectral band to generate alerts and notifications;

- Daily notifications of assets in alert and/or critical state (via e-mail);

- Backup of parameters of AC drives, soft-starters and intelligent relays;

- Module for analyzing vibration signals, in spectral mode and in the time domain, to perform diagnostics;

- Maintenance module with CMMS (computerized maintenance management system) functionalities for creating and managing management of maintenance orders, execution resources and planning;

- WEGscan application for sensor activation, instantaneous measurements and ODS (Operating Deflection Shape) analysis;

- WEG Digital Notify application integrated with the Maintenance Module to speed up the flow of information to the team;

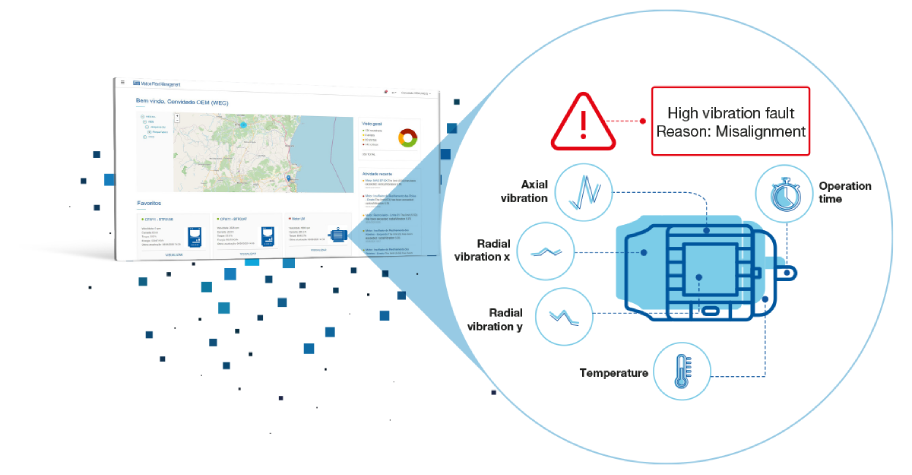

- Specialist modules with Analytics and Artificial Intelligence for autonomous fault diagnosis;

- Exchange modules for integration (via REST API) of data with other platforms and solutions.

Advantages and Benefits of the WMFM Solution

- Monitoring of various types of equipment, assets and plants in a single environment;

- Ecosystem in constant development, both hardware and software;

- Solution integrated with WEGscans, dedicated and robust hardware for the acquisition of application data;

- Data processing at the edge and in the cloud, enabling advanced diagnostics;

- Ready-to-use solution, suitable for a wide variety of equipment and assets, just register the WEGscan in the application and use it;

- Enables maintenance management based on the operational condition of the assets;

- Flexible solution available to service providers;

- Technology to enable the reduction of the plant's operational cost (TCO, Total Cost of Ownership);

- Multilanguage solution and available globally.

Structure

WEG Motion Fleet Management is a modular solution, with a flexible, layer-based structure that adapts to customers' needs. Assets.

Assets

WEG Motion Fleet Management allows on-line monitoring of low and medium voltage motors and drives, as well as gearboxes, gearmotors, compressors, pumps and fans/exhausters.

Scan

WEG Scans and Gateways are hardware responsible for data collection and connectivity of assets to the WEG cloud server, which hosts the WEG Motion Fleet Management application. To monitor the motors, the WEG Motor Scan and Gateway Cassia X1000 is applied, the data upload can be via gateway or smartphone. As for the low or medium voltage drives, the data upload is performed by the WEG Drive Scan.

Management Layer

The Management layer of the WEG Motion Fleet Management application receives data from the WEG Scans and allows the exploration of the functionalities present in the solution. Remember that the solution is constantly improving and new features will be frequently incorporated into the solution. Additionally, users can complement their experience with the Specialist and Exchange modules. They can access the system from anywhere via the Internet whenever a subscription plan is available, which is annual.

Users can view information related to the monitored assets, such as:

- Asset operational condition information (normal, alert or critical);

- Operating parameters such as:

- Rotation;

- Temperature;

- Vibration;

- Power;

- Consumption;

- Current;

- Voltage;

- Operation History;

- Failures/Events and interventions;

- Configurable alerts and notifications.

Diagnostics & Integration

With active subscriptions to the WEG Motion Fleet Management layer, users can complement their experience with subscriptions to specific modules such as WEG Specialist and WEG Exchange.

Specialist Module

The Specialist module applies algorithms specially developed by WEG for advanced data analysis, by means of Machine Learning and Artificial Intelligence. These algorithms are applied to the data collected by WEG Scans and thus generate useful information, something essential for efficient fleet management. As is the case of WEG Motor Specialist, which has a sub-module for diagnosing mechanical failure and another for evaluating the engine's energy consumption. Both functionalities were developed by WEG's team of specialists and were validated in the company's laboratories.

These advanced analysis algorithms observe and learn the patterns and operating deviations of the monitored electric motor, generating failure indicators for unbalancing, misalignment, rolling (advanced failure) and external vibration. This type of information is very useful for operation and maintenance staff, as it aids in decision making, speeds up the repair process, and minimizes unscheduled downtime. In order to use the Specialist layer, the respective asset(s) must have an active WEG Motion Fleet Management subscription. Both subscriptions are annual and per asset.

Exchange Module

The Exchange module allows the customer to integrate the information collected and present in WEG Motion Fleet Management in its own management system and/or platforms. Through periodic and automatic data requests of the Web Service REST type, the WEG Motion Fleet Management data is sent to the customer's system or a third party system. To use the Exchange layer, the respective asset(s) must have an active Management layer subscription. Exchange subscriptions are annual and per data packet.

WEG Drive Scan

Developed to connect low voltage inverters to WEG Motion Fleet Management, the WEG Drive Scan line periodically collects and transmits important data from the inverters, allowing monitoring to be done at any time and from anywhere in the world.

Access the catalog and learn more.

WEG Motor Scan® + Specialist

WEG Motor Scan® is the monitoring solution for total control of the manufacturing plant, ensuring, via predictive analysis, the level of excellence in the performance of electric motors and other equipment. With it, data is extracted and sent to the cloud, allowing preventive actions and avoiding risks of production stoppage. The industry will never be the same again!

Access the catalog and know more.

KNOW MOREAre you in doubt?

Check out the most frequently asked questions.

You must be a plant administrator to grant access to others. You can do that in the “Menu” - “Users” panel. Select the Group you want to allow access to and click on “Search”. Click on the “+Add/Change plant access” button, add the email of the person you want to add, and choose the type of access to be granted.

To activate/enable the sensor, use the mobile app, click on "New Device", then "Select" and "Enable". Then, position the sensor according to the instructions provided by the application. Attention: once enabled, the sensor must be configured within five (5) minutes; otherwise, it will automatically return to the disabled mode.

The WEG Motor Scan has the following dimensions: 25x44x38 mm (HxWxD).

The WEG Motor Scan uses a lithium battery with an estimated service life of up to 3 years. The battery is not rechargeable or replaceable.

When the battery charge ends, the WEG Motor Scan must be discarded as indicated in the product manual. As it is an electronic device, local rules for selective collection of electrical and electronic equipment must be observed.

Más información sobre las novedades de WEG sobre la industria 4.0

Una nueva forma de combinar personas, negocios, tecnología y eficiencia

Acceda a nuestro sandbox de forma gratuita y vea cómo la transformación digital está impactando los mercados industriales y revolucionando la forma en que producimos.

CONOZCA MÁS¿Te ha gustado WEG Digital Solutions y quieres saber más?

Elija una de las opciones siguientes:

¿Quiere recibir nuestras noticias?

Póngase en contacto con nosotros y haga sus preguntas.