Through the company's strategic direction for its business model, WEG has, in all its business units, more efficient solutions and products with less environmental impact, such as renewable energy (solar and wind power), electric mobility and energy efficiency. WEG develops products considering strict risk criteria related to health and safety. In the development phase, analyzes such as Quality Function Deployment (QFD) and Risk Assessment are applied.

Below are some highlights, considering the variety of products and solutions that the company provides to the market through its different business units.

Energy and Industrial Efficiency

W51 HD Motor (High Density)

Efficient and compact solution thar delivers high performance with reduced size and weight in comparison to the previous line (up to 25% higher power density – kW/kg) and its competitors. Therefore, it makes rational use of raw materials in the manufacture of motors and reduces the potential effects of their transformation, cutting down GHG emissions by about 15% in comparison to the previous line.

VSD for Motors

High-tech VSD for driving and controlling three-phase induction and permanent magnet motors. Thanks to its technology, this VSD model provides energy savings, safety, increased productivity and quality in the process network in which it is implemented. The CFW900, together with permanent magnet motors, offers the highest energy efficiency solution on the market. The new HMI with Bluetooth® connectivity is ideal for panel builders and repair shops, enabling programming, monitoring, parameter backup and other functionalities via tablets or smartphones.

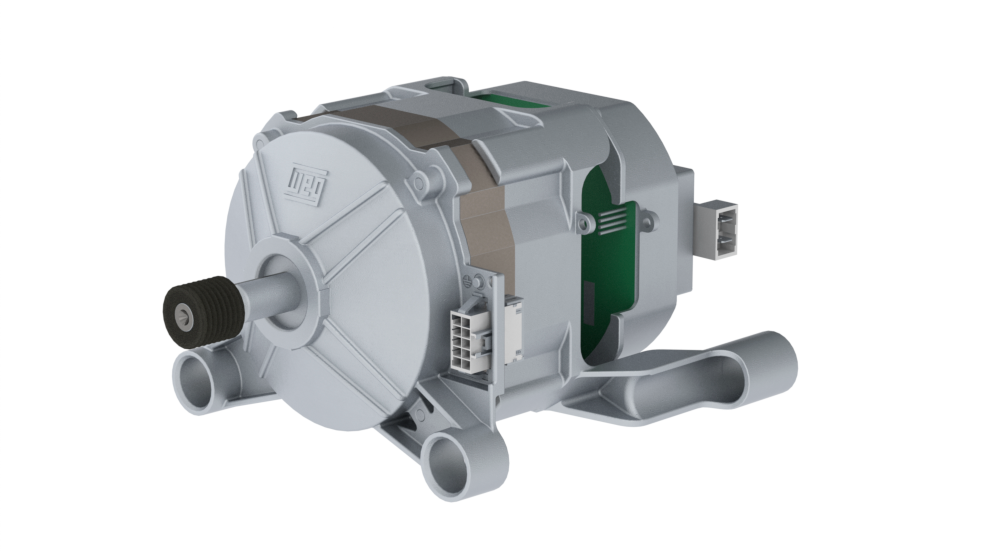

BLDC Motor Line (Brushless DC)

For application in front load washing machines, it delivers a 60% improvement in the performance of the operating cycle and, consequently, a reduction of GHG emissions during the operation phase. This line currently represents 20% of the volume sold by WEG for front load washing machines.

Energias Renováveis

Energia Eólica

Em julho de 2022, a WEG anunciou o lançamento de uma nova plataforma de aerogeradores com potência de 7 MW e 172 metros de diâmetro de rotor das pás. Esse aerogerador se tornará a maior máquina em operação no mercado brasileiro. Mais potente e eficiente, o novo modelo traz maior geração para os projetos eólicos.

Energia Solar

A WEG se consolida como um dos principais fornecedores de produtos e soluções para usinas solares do Brasil levando a eficiência que impulsiona a sustentabilidade nas cidades, nas indústrias, no agronegócio e nos lares de todo o país. A WEG possui um vasto portfólio de produtos para projetos de geração solar fotovoltaica em todas as etapas do empreendimento, com soluções para o sistema de conversão de energia e de distribuição interna da planta até o ponto de conexão com o sistema elétrico por meio das subestações de alta tensão.

Geração Hidrelétrica

A WEG foi selecionada para fornecer os geradores da UHE São Roque, situada em Vargem/SC. Os geradores são uma das partes mais importantes que compõem o empreendimento para a UHE São Roque. Com 285 toneladas cada e aproximadamente oito metros de diâmetro, estes equipamentos estão entre os maiores hidrogeradores elétricos já produzidos pela WEG.

A UHE São Roque tem potência instalada de 142 MW que, em média, é suficiente para abastecer uma cidade com aproximadamente 170 mil habitantes. Os geradores entraram em operação comercial em julho de 2022.

Armazenamento de Energia Comercial e Industrial

Os sistemas de armazenamento de energia são utilizados em instalações comerciais ou industriais, sendo a solução completa para armazenamento e gerenciamento de energia elétrica armazenada, podendo ser configurados para desempenhar várias funções em sistemas inteligentes de geração, transmissão e distribuição de energia elétrica. O sistema é composto por uma solução de controle e gestão energética, sendo indicado principalmente para aplicações em sistemas instalados atrás do medidor em indústrias, comércios, shopping centers, condomínios residenciais e infraestrutura de mobilidade elétrica.

Transformers for Renewable Energy

The reliability of the transformers developed for solar plants aims at guaranteeing the supply of energy, allowing access to electricity through renewable energy generation sources. In the line of transformers for wind farms, WEG developed an extremely compact electrical and mechanical transformer design. Additionally, due to the installation layout, in which the source and the transforming unit are very close to each other, the system produces smaller losses and greater energy efficiency.

Electrical Mobility

Integrated solutions for electric vehicles

WEG continually develops innovative technologies to create electric traction systems, as well as all the electrical infrastructure necessary for the operation of electric vehicles. WEG electric traction systems can drive various road, rail and navigation vehicles, such as urban trucks and buses, vans, forklifts, trains, monorails, support vessels and tugboats.

Digital Solutions

Smart and sustainable systems

Smart systems are able to integrate different devices and machines, as well as installations and processes, promoting efficiency in decision-making and increasing operational efficiency. Smarter solutions and systems also promote more efficient use of energy resources helping reduce the carbon footprint of operations at all levels.

Automation Systems

WEG supplies completely integrated control systems that guarantee high performance of industrial processes, easy operation and productivity gains by means of state-of-the-art technology. The success of the integration of this system is in the synergy of WEG products, where motors, drives, generators, electric panels and software applications are integrated, providing the ideal solution for each requirement. The control of industrial processes requires automation systems with high reliability and uptime levels, in addition to easy asset management by the maintenance teams, extending the equipment service life and streamlining the use of resources.

WEG Transformer Fleet Management and WEG Power Transformer Specialist

WEG Transformer Fleet Management is the ideal solution to monitor online and manage the fleet of oil or dry-type transformers, enabling customers to maximize the efficiency of their operations, supporting the streamlined management of industrial plants, renewable energy generation and infrastructure. WEG Power Transformer Specialist is a digital solution used to monitor and manage power transformers that, integrated with the WEG Transformer Fleet Management platform, centralizes the signals from several sensors installed on the equipment.

WEG Motion Fleet Management

Developed to simplify and speed up the operation, maintenance and management of industrial plants, WEG Motor Fleet Management is the ideal solution for monitoring and increasing the uptime of the industrial drive fleet. Based on cloud computing technology, the performance of assets can be monitored at any time, from any part of the world. WEG Motor Fleet Management allows checking the operating status of low and medium voltage motors and drives (VSDs and soft-starters), gearboxes, gearmotors, compressors and other assets installed in any kind of industry or facility.

Ultra Low Bake (ULB) Technology for Coatings

The Ultra Low Bake (ULB) technology consists of reducing the curing time or curing temperature of powder coatings. Linked to this reduction in time or temperature (which can reach up to 35%) is the reduction in the amount of gas used in the curing ovens of customers and partners, lowering GHG emissions.

WEG partners who employ such technology in their production line, in addition to reducing environmental impact, have a significant increase in productivity and competitiveness. WEG has forty products developed for this purpose.

Material efficiency and environmental assessment of the product

In its value chain, WEG adopts initiatives in line with the principles of the circular economy, using practices that include the reuse of process residues as raw material, like stamping steel scrap used to make castings, and the adoption of programs to recover materials at the end of the product life cycle through reverse logistics and replacement plans.

The application of these concepts and practices allowed WEG to achieve a material efficiency rate close to 85%. WEG is also constantly improving and evolving the energy efficiency of its products and retrofit solutions to extend the service life of some product lines. Qualified teams work on the processes to develop new products, on the design of new lines and in the implementation of more efficient industrial processes.

WEG applies the LCA (Life Cycle Analysis) to generate the EPD (Environmental Product Declarations) according to the customers’ demands, intending, in the coming years, to expand the application of these tools.